Wathba istps

Project:

Wathba ISTP Sludge Tanks Odor Control System

- Location: Abu Dhabi-UAE

- Client: VeBes

- Capacity: 6,000~9000 m3/hr

- Design: 1 Vertical Bio Scrubber

- Performance: 200~500 ppm 99.5%

- Year: Installation/Commissioning:2012/2012

AmerAir International, AAI, is a leading supplier of Odor Control Systems in the Gulf Area for the last 7 years. Wathba ISTP Sludge Tanks Odor Control System are being presented as samples of our supplied systems. AAI scope of work included the initial conceptual design, detailed engineering and design, equipment supply, installation, commissioning, testing, training and follows up support to the completion of defect liability period and final hand over of the projects.

Background

In 2011, during the commissioning of Wathba ISTP2 by OTV(joint venture of Veolia and BESIX), AAI was approached to provide odor control consultation for improving the odor control in the plant. AAI immediately identified several sources of odor problems and made its recommendation. One main area of odor releases was the anoxic zone of the biological Sludge Tanks. AAI’s recommendation lead to the installation of the first and longest operating Bio Trickling Scrubber in Abu Dhabi.

The BTS odor control system collects the odorous emissions from the anoxic zone of Sludge Tanks and pushes the odorous air through a BTS with a capacity of 6,000-9,000 m3/hr. This system has been in operation since March of 2012 and has achieved all specification requirements. Exceptional performance at very high mass loadings and very low residence times are recorded by AAI and the VeBes (Veolia and BESIX) operators at extremely low residence times of about six seconds. The system was inspected and tested after two years of operation with very satisfactory results.

The entire conceptual design of the system was done by AmerAir International. AAI also supplied the detailed design, supply of equipment, complete installation of the ventilation system, commissioning, training and technical support.

Design Key Point

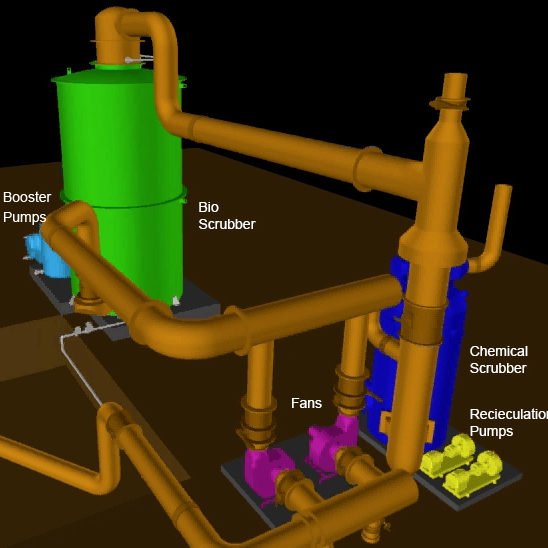

This system consists of a Bio Trickling Scrubber and Fans. The flow is passed through Bio Trickling Scrubber as the main treatment stage by two Fans (duty/stand-by). Then the treated air is pushed to the existing Chemical Scrubbing system.

The Bio Scrubber is equipped with all internals and irrigation line. The TSE water is used as make-up water of scrubbing solution to remove the H2S.

The system is equipped with necessary instrumentation to control and monitor the operation.

Service conditions

Ambient Temperature: +1~ +55°C

Relative Humidity: 20~100%

Our design is based on following design data:

| Pos. | Parameter | |

|---|---|---|

| 1 | Exhaust flow rate, wet, operation conditions | 6000~9000 m³/h |

| 2 | H2S-inlet concentration | 200~500 ppm |

| 3 | Minimum H2S-removal efficiency at average load | 99.5% |

System Performance

These systems have been in operation since March of 2012 and have achieved all specification requirements. Exceptional performance at very high mass loadings and very low residence times are recorded by AAI and the VeBes operators at extremely low residence times of about six seconds. The system was inspected and tested after two years of operation with very satisfactory results.